Specifications for Oil Refining Production Line

| Machine Type | Oil refining machine |

| Capacity | 1TPD, 3TPD, 5TPD, 10TPD, 20TPD, 30TPD...1000TPD |

| Working Type | Continuous oil refinery plant, Batch oil refinery plant |

| Automatic Degree | Fully Automatic, Semi-Automatic |

| Applicable Material | The process is suitable for most oil products (including lard, chicken oil, beef tallow, fish oil, soybean oil, peanut oil, rapeseed oil, corn oil, cottonseed oil, rice bran oil, palm oil, peony seed oil, tea seed oil, flax seed oil, etc.) |

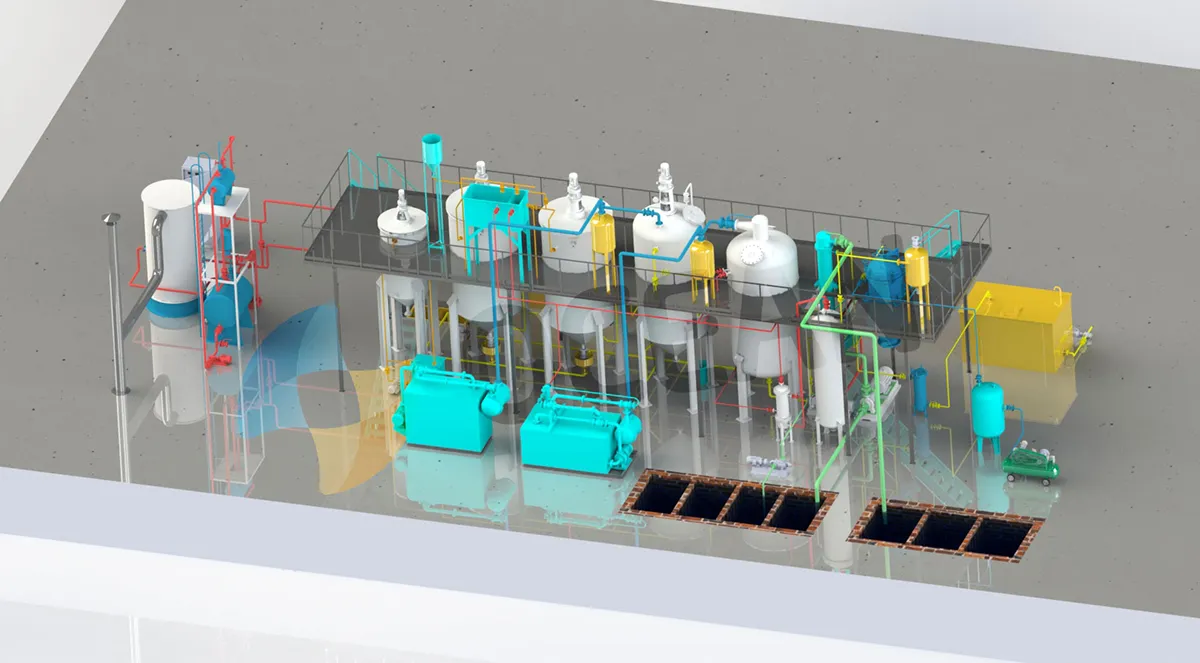

Process Description for Continuous Oil Refinery Plant:

Oil refinery is to selectively separate oil accompaniment from oil by physical and chemical methods. It aims to remove harmful ingredients to human body to enhance oil storage stability, to improve oil flavour and color.

Oil refinery process includes hydration degumming, alkali deacidification, absorption decolorization, high-temperature vacuum deodorization. Continuous refinery line comprises of the following different processes:

------Degumming&Deacidification

------Bleaching Section

------Deodorizing Section

------Dewaxing section

With our refining equipment and technology, you can:

—— Low temperature long-mixed alkali refinery process

——Reduce operating costs

——Zero sewage discharge degumming process

——Low carbon, energy saving and environmental protection chilling vacuum system design

Oil Refining Machines and Their Primary Functions

Oil Refining Machine | Primary Function | Why It's Essential |

Centrifuge Machine | Separates impurities using centrifugal force | Ensures oil clarity and purity by removing impurities. |

Neutralization Reactor | Neutralizes free fatty acids (FFAs) in the oil | Enhances oil shelf life and improves taste and odor. |

Washing Equipment | Removes impurities and soap particles | Guarantees oil purity and prevents emulsions. |

Bleaching Equipment | Removes color and further impurities | Provides clear oil and enhances stability. |

Filtration Units | Filters out particles and sediments | Ensures smooth oil texture and prevents clogging. |

Deodorization Unit | Eliminates undesirable odors and flavors | Offers neutral oil aroma for various uses. |

Why choose Fuerstar?

We have supplied equipment and services to more than 300 leading domestic and international oil & fats companies, and our products have been exported to more than 30 countries in Africa, Southeast Asia, Central Asia, Latin America, and Europe, which means that we know every piece of equipment and every component of your specific process, and we can provide customized solutions to meet your varying needs, ensuring optimal efficiency and performance.

Please fill the below "CONTACT" Form so that we can contact and provide you the best solution for your requirement.