Edible Oil Plant Capacity: 1- 1000 Tons /Day

It can use for Sunflower seeds, soybeans, peanuts/groundnuts, oil palm, palm kernel, mustard seeds, cottonseed, corn germ, sesame seeds, rice bran, coconuts/dried coconuts, and tea seeds and so on.

Technology for Vegetable Oil Making Plants:

Raw materials – Pre-treatment section – Pre-pressing – Extraction section(physical squeezing/solvent extraction) – Oil refining sector – Edible oil filling

Edible oil production line main equipment:

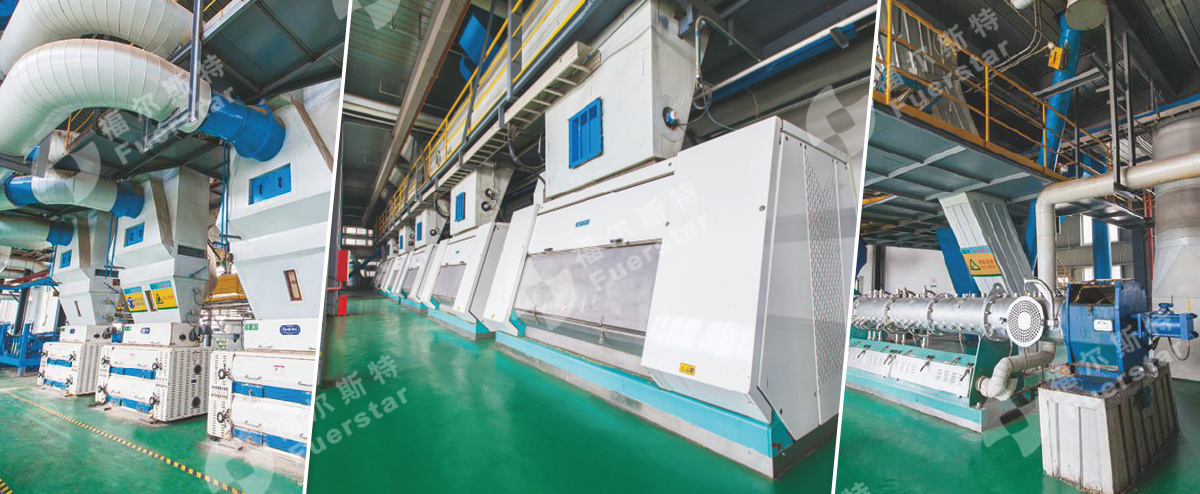

1、Oilseeds Pretreatment Equipment

Pre-treatment of oilseeds includes oilseed cleaning, oilseed moisture temperature adjustment, embryo rolling, crushing and other methods. It aims to regulate the state of oilseeds to make them meet the subsequent pressing or leaching requirements.

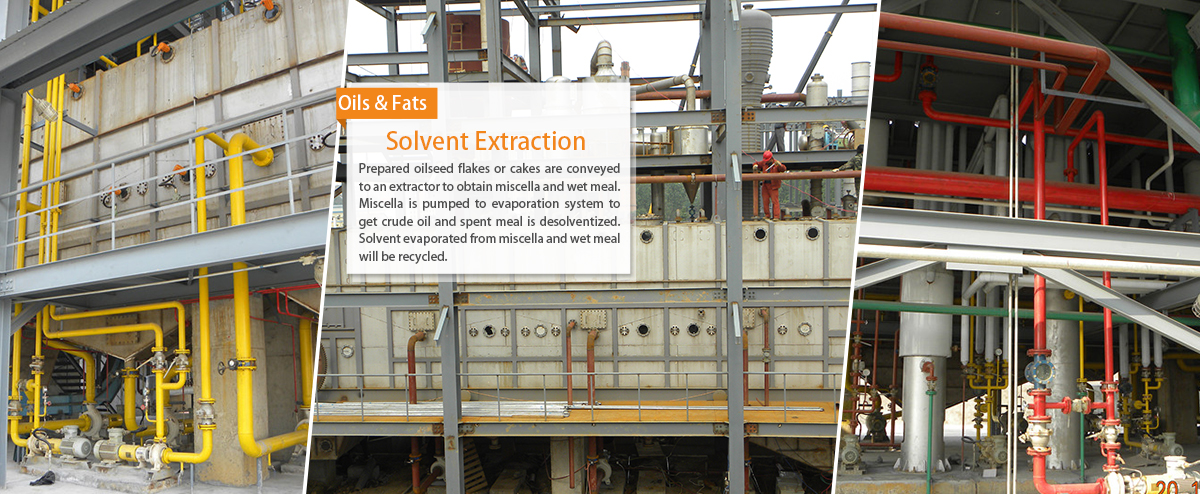

2、Oil Pressing/Solvent Extraction Equipment

Oil pressing refers to the physical method of squeezing the oil out of the oil material and it is for small capacities like 1-50TPD. There are usually cold pressing and hot pressing, and the pressed oil is called crude oil. If bigger input capacities, usually adopt solvent extraction method to get oil as much as possible.

3、Crude Oil Refining Equipment

Oil refining is the process of selectively separating the accompanying substances from the oil by physical and chemical means. The aim is to remove harmful components, enhance the storage stability of oils and fats, and improve the flavor and color of oils and fats.

4、Filling Workshop Equipment

The products cover : edible oil filling machine , capping machine , labeling machine ,inkjet printer , conveyor line and other complete production lines , which can be customized and adjusted according to customer requirements for different production lines

What kind of support we can provide:

We are ready to perform adjustment, commissioning and start-up of Fuerstar equipment:

Warranty period – 12 months since the machines installed or 18 months since we deliver the equipment, whichever matures the first.

**Even if the warranty period expires, it will not affect our after-sales service. We will always provide online support.

Whether you need a small or large oil mill, we have professional technical support to help you build a new oil mill to get quick returns!

Please fill the below "CONTACT" Form so that we can contact and provide you the best solution for your requirement.