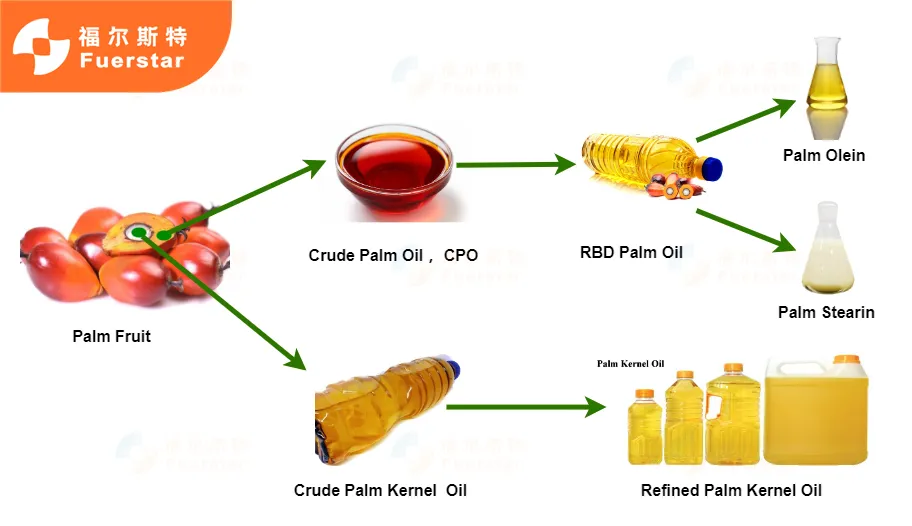

Fuerstar is a leading provider of palm oil refinery plants, offering comprehensive solutions for processing crude palm oil (CPO) into high-quality edible oil. Our plants are designed to handle capacities ranging from 5 to 1000 tons per day (TPD), catering to the diverse needs of oil producers worldwide.

Palm Oil Refining Process: Transforming CPO into Edible Oil

The palm oil refining process involves a series of steps that remove impurities, enhance stability, and improve the overall quality of the oil. Fuerstar's palm oil refinery plants employ a combination of physical and chemical refining techniques to achieve optimal results.

Key Stages of Palm Oil Refining

Degumming and Deacidification: In this stage, impurities such as gums and free fatty acids are removed from the crude palm oil. This is done using a combination of water washing and neutralization with alkali.

Bleaching: In this stage, the color of the palm oil is removed. This is done using bleaching clays and other adsorbents.

Deodorization: In this stage, the odor and flavor of the palm oil are removed. This is done by stripping the oil of volatile compounds under high vacuum.

Fuerstar's Palm Oil Refinery Plant: A Benchmark in Efficiency

High-quality refined palm oil

Energy-efficient and environmentally friendly

Wide range of capacities

Advanced technologies

Proven track record

Contact Fuerstar Today

Partner with Fuerstar and experience the difference of our superior palm oil refinery plants. Contact us today to discuss your requirements and embark on a journey towards producing high-quality edible oil that meets the ever-growing global demand.