Introduction of Fully Automatic Oil Production Line

Edible oil is one of the nutrients that people are indispensable for daily diet. Therefore, if the automatic filling machine is used in the simple packaging production mode, different sizes of bottle containers are gathered to be put into the feeding tray and then goes to the conveyor belt. Then the filling machine assists to divide the bottles into small packages and large packages.

Full-Automatic Filling Machine for Small Package

Application Field

| _______ | 2-heads | 4-heads | 6-heads | 8-heads | 10-heads | 12-heads | 16-heads |

| Conveyor Belt Length (m) | 6 | 9 | 9 | 10 | 11 | 12 | 12 |

| Capacity (bbl/h) | 300 | 700 | 1000 | 1300 | 1600 | 1900 | 2500 |

| Filling Range (ml-L) | 50-5 | ||||||

| Accuracy | ±2‰ | ||||||

| Power Supply (V) | 380 ± 10% | ||||||

| Power Source (MPa) | 0.4 - 1.0 | ||||||

| Remarks | 5L of growth power | ||||||

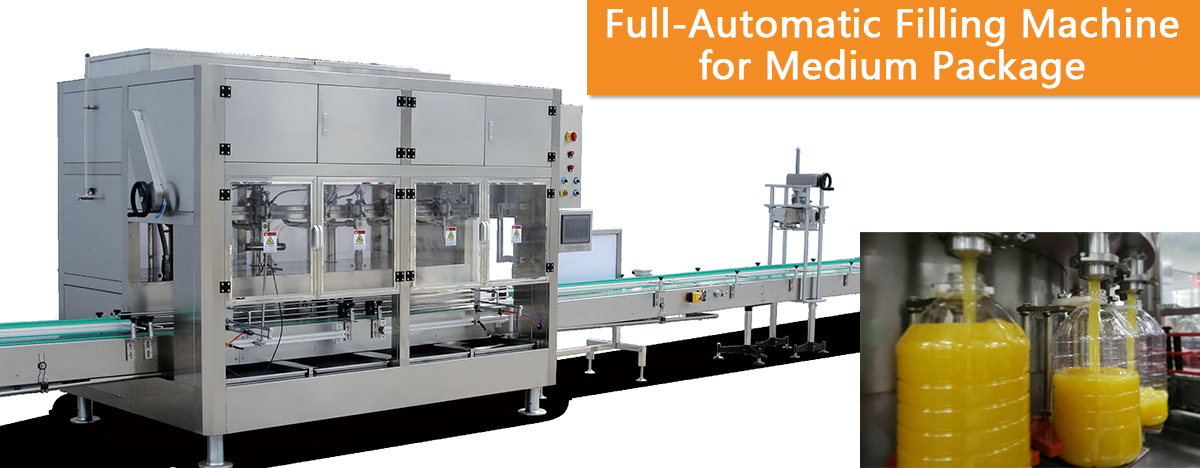

Full-Automatic Filling Machine for Medium Package

Application Field

| _______ | 2-heads | 4-heads | 6-heads | 8-heads | 10-heads | 12-heads |

| Conveyor Belt Length (m) | 6 | 9 | 10 | 10 | 12 | 15 |

| Capacity (bbl/h) | 300 | 600 | 800 | 1000 | 1200 | 1400 |

| Filling Range (ml-L) | 10-25 | |||||

| Accuracy | ±1‰ | |||||

| Power Supply (V) | 380 ± 10% | |||||

| Power Source (MPa) | 0.4 - 1.0 | |||||

| Remarks | 20L of growth power | |||||

Product Characteristics

1. First-line branded centerpiece components: Ensure the performance of the equipment and the accuracy of filling.

2. Self-contained transit tank: for more stable filling accuracy.

3. Western-style PLC from Germany: Global brand, fast computing speed and stable performance.

4. Touch screen operation: friendly interface, simple operation;

5. Double-section independent conveyor: filling and capping are operated independently, the process is smooth and reasonable.

6. Caterpillar capper: stable and reliable, no empty pressure phenomenon

Please fill the below "CONTACT" Form so that we can contact and provide you the best solution for your requirement.