Soap is the most common and widespread detergent in people's daily lives, the main raw materials for soap manufacturing are caustic soda, and some by-product which produced from refinery process.

Raw Materials:

| Raw Material Type | Raw Material |

| Animal Oil | Any two or more of butter, lamb oil, lard, chicken and duck oil, bone oil, gutter oil, etc. |

| Vegetable Oil | Cottonseed oil, sunflower oil, palm oil, coconut oil, coconut acid and any two or more of the plants |

| Others | Caustic soda, alkali, salt, bleaching liquid, flavoring, soap yellow |

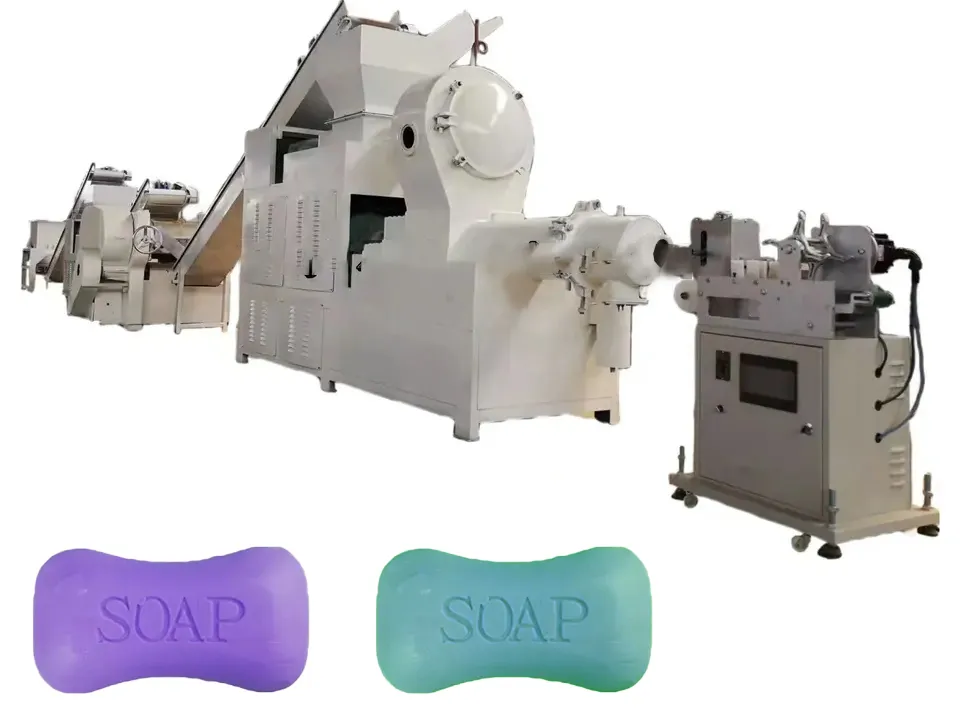

Oil-Fat Saponification, Soap Complete Production Line

The technological process of soap production includes refining, saponification, salting out, washing, and alkali precipitation before it can be produced into soap.

Soap Production Line Parameters:

| Capacity(kg/h) | Plant Area(㎡) | Plant Height(m) | Labor | Water(m³/h) | Electricity(kw/h) | Gas(m³/h) |

| 500 | 300 | 4 | 3-5 | 2 | 30 | 2 |

| 1000 | 500 | 4 | 5-8 | 4 | 50 | 4 |

| 2000 | 800 | 4.5 | 8-10 | 6 | 80 | 8 |

| 3000 | 1000 | 5 | 10-12 | 8 | 100 | 12 |

Advantages of Soap Making Machine:

The production of fatty acid content from 38%-70% of a variety of soap products.

Production capacity from 50-5000kg/h.

The size of soap depends on the customer's requirements

Smooth running, more precise and quiet.

Easy to operate