Introduction to Cassava Flour

Cassava flour is made from the entire cassava root being dried and ground into flour. This being so, it contains all the nutrients that the root would. Renowned for its nutritional value and culinary flexibility, cassava flour has gained popularity worldwide.

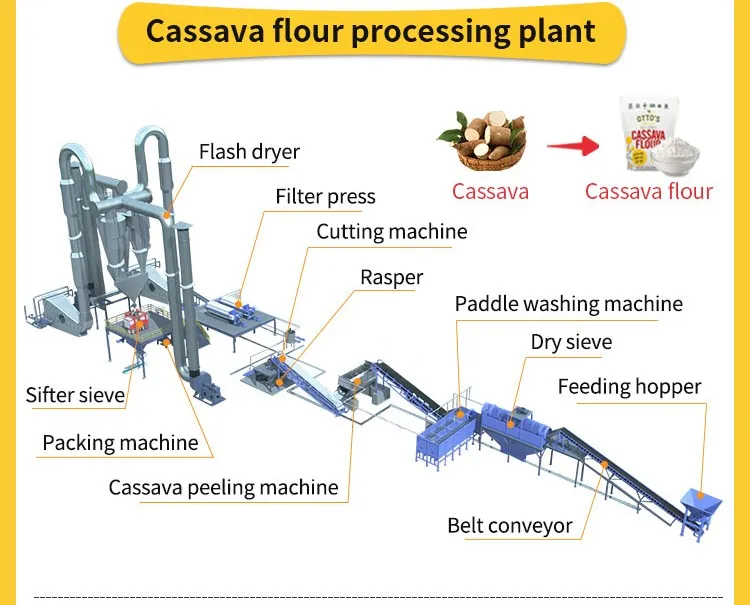

5-20 T/H CASSAVA MILLING PRODUCTION LINE

With years of expertise in cassava processing, we pride ourselves on delivering superior quality cassava flour production solutions. Our cassava flour making machine is capable of processing anywhere from 5 to 20 tons per hour, catering to the needs of both small-scale enterprises and large industrial operations.

The production technology of cassava milling project is as follows:

Our cassava flour production line is equipped with state-of-the-art machinery to ensure the highest quality and efficiency in processing. Key machines include: cassava cleaning and washing machine, cassava crushing machine(rasper), plate frame filter press(dewatering), flash dryer, sieving and packing machine.

Main Machines

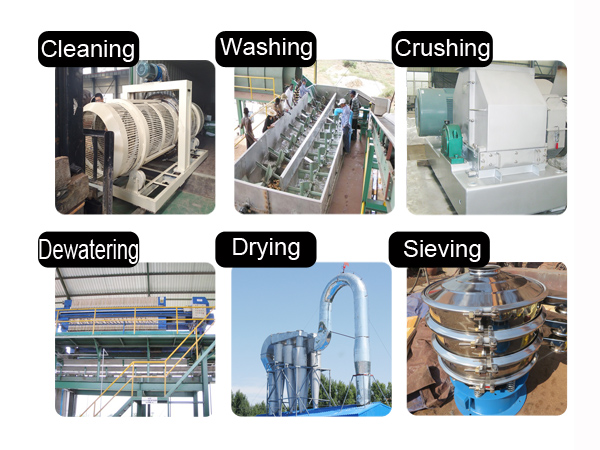

1. Cassava Cleaning and Washing Machine: After dry sieve to remove the dirt on the appearance, Paddle washing with clean water is required to remove soil particles and dirt which would meet the quality of the final cassava flour.

2. Cassava Crushing Machine (Rasper): We match cutting machine and rasper to ensure the fineness of final cassava flour.

3. Plate Frame Filter Press (Dewatering): Normally, it needs filter and plate press,Pressing is use to remove the starch milk inside of the cassava pulp. And then get a dewatered cake, the screw conveying machine will break the cake and make it into mesh for drying section

4. Drying Section: We match the flash dryer, which can dry the high quality cassava flour in 2 seconds, To get more dry and high quality cassava flour.

5. Sieving and Packing Machine: Dried cassava flour are milled in a fine mill to a fine and uniform particle size.. Flour is screened using a motorized flour sifter fitter with a 250µm screen. This removes fiber and improves the smoothness of the flour. Finally packaged by packaging machine or manual work.

Advantages of cassava milling project:

Simple structure, easy installation and maintenance.

Adopt world advanced famous brand motor, electrical parts, bearings and running parts.

The dust can be collected in the dust collecting box.so there is no dust in the production process.

During the production process, the temperature is kept normal and will not get hot. So the color and properties of the material will not change.

Please fill the below "CONTACT" Form so that we can contact and provide you the best solution for your requirement.