Egg tray machine is also called pulp molding machine. Pulp molding is athree-dimensional papermaking technology. lt uses pulp as raw material and amold with a filter to dehvdrate the pulo under pressure (negative pressure or positivepressure). The processing method of forming to produce the desired product.

Capacity :1000Pcs/h ,1500Pcs/h ,2000-2500Pcs/h ,3000-4000Pcs/h ,4500-6000Pcs/h and so on.

Egg Tray Machine Model Specifications:

| Model | Capicity/hr | Mould | Total Power | Worker | Vacuum Pump | Pulper |

| BMD-1-3 | 1000pcs | 3units | 46KW | 3-4 people | 7.5KW | 7.5KW |

| BMD-1-4 | 1500pcs | 4units | 59KW | 3-4 people | 12KW | 7.5KW |

| BMD-3-4 | 2000-2200pcs | 12units | 46KW | 3-5 people | 22KW | 7.5KW |

| BMD-4-4 | 2200-2500pcs | 16units | 46KW | 4-6 people | 22KW | 11KW |

| BMD-4-8 | 3000-4000pcs | 32units | 46KW | 4-6 people | 15KW+15KW | 11KW |

| NEW HY-4-8 | 3500-4500pcs | 32units | 46KW | 4-6 people | 22KW+18.5KW | 22KW |

| BMD-5-8 | 4500-5500pcs | 40units | 46KW | 5-7 people | 30KW+30KW | 22KW |

| BMD-5-12 | 5000-6000pcs | 60units | 46KW | 5-7 people | 22KW+22KW+18.5KW | 22KW |

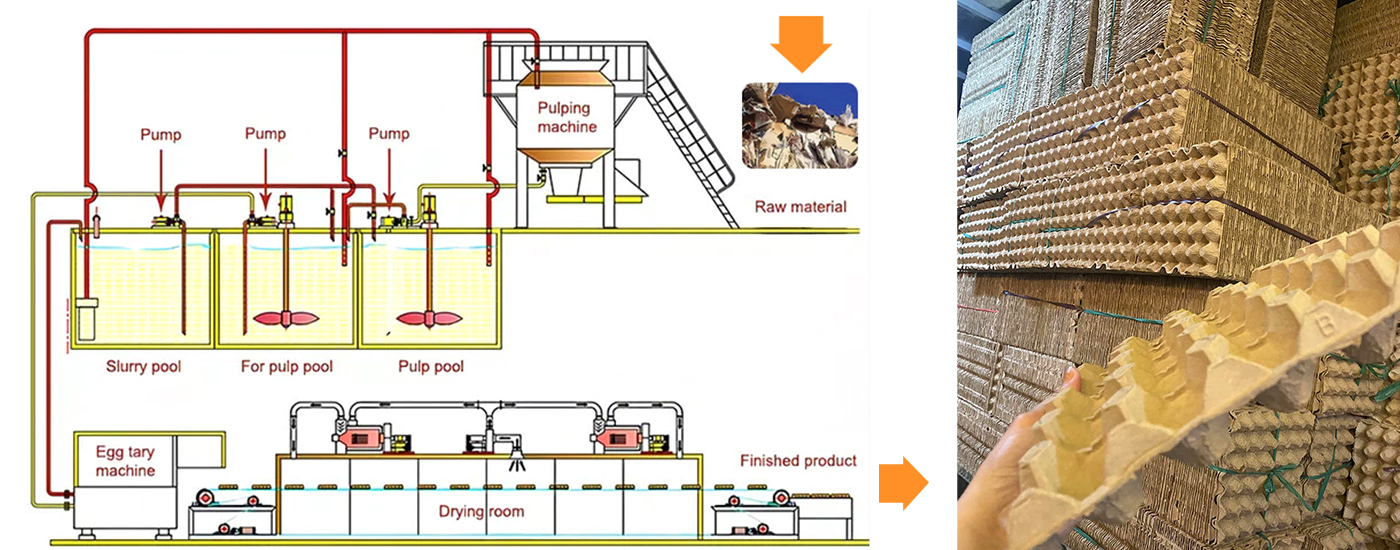

Egg Tray Production Line:

Fuerstar egg tray production line can turn waste paper into valuable egg trays and pack them in stacks, it has the characteristics of high efficiency and fewer labor. Many egg tray manufacturers choose the whole egg tray production line.

1.Pulp Making System: pulper, homogenizer, pulp pump, vibrating screen, pulp decomposer.

2.Molding System: molding machine, mold, vacuum pump, negative pressure tank, water pump, air compressor, mold cleaning machine.

3.Drying System: Natural drying method, traditional drying, new multi-layer drying line.

4.Packing Equipment: Automatic stackers, balers, transfer conveyors.

Please fill the below "CONTACT" Form so that we can contact and provide you the best solution for your requirement.